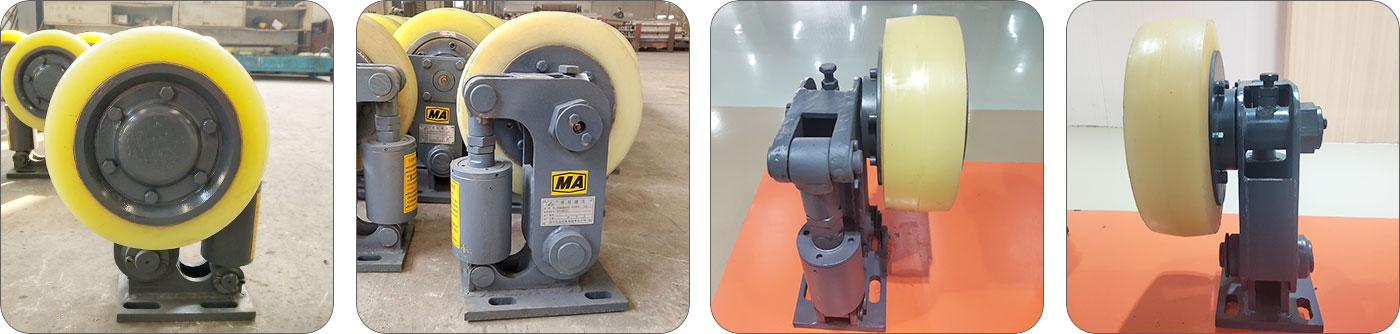

Application environment of LS50 roller can ear

滚轮罐耳结合我国矿山特点为目前运行中的提升容器更换新型滚轮导向装置提供了便利条件,

广泛应用于矿山,煤炭等工业生产部门。

Combined with the characteristics of China's mines, the roller can ear provides convenient conditions for the current

operation of the lifting container to replace the new roller guide device, which is widely used in mines, coal and other

industrial production departments.

滚轮罐耳沿罐道运行时,因罐道的设计安装,会产生接点、弯曲高点,轮头会受到水平推力作用,

由于支臂架、底座和缓冲器之间的铰接作用,使缓冲器受压缩产生反弹力。

How to use LS50 roller can ear

根据滚轮磨损情况,应对滚轮进行调整,方法是松开螺杆锁紧螺母,转动螺杆使滚轮靠向罐道,

间隙0~2mm,调好后紧固锁紧螺母。

According to the wear condition of the roller, the roller should be adjusted by loosening the screw lock nut, turning the screw to make the roller close to the tank channel, with a gap of 0 ~ 2mm, and then tightening the lock nut.

HLS50 roller can ear product parameters

| 【型号】:LS50 | 【承受最大水平力(kN)】 : 45 |

| 【重量(kg)】 : 500 | 【缓冲行程 mm】: 10-14 |

| 分类 | 型号 | 滚轮直径mm | 最大水平力KN | 缓冲行程mm |

| 单轮 | L25 | 250 | 12 | 10~14 |

| L30 | 300 | 16 | ||

| L35 | 350 | 24 | ||

| L42.5 | 425 | 33 | ||

| L45 | 450 | 35 | ||

| L50 | 500 | 36 | ||

| 双轮 | LS30 | 300 | 20 | |

| LS35 | 350 | 28 | ||

| LS42.5 | 425 | 42 | ||

| LS45 | 450 | 44 |

Precautions for LS50 roller can ear

滚轮罐耳应定期维护,滚轮罐耳的轴承6个月加注一次润滑脂,滚轮、支架、弹簧缓冲装置、底座每年检查一次,对螺纹、弹簧、轴销等重新加注润滑脂。

The roller can ear should be maintained regularly. The bearing of the roller can ear should be filled with grease once every 6 months. The roller, bracket, spring buffer device and base should be inspected once a year. The thread, spring and axle pin should be re filled with grease.

滚轮每半年应加注一次防水润滑脂,加注量为0.2升;新轮出厂前已加注润滑脂,请不要再加注。

The roller should be filled with waterproof grease once every half a year, and the filling amount is 0.2L; The new wheel has been filled with grease before leaving the factory, please do not fill it again.

在使用中应每班检查滚轮工作情况,如发现螺栓松动、滚轮或摆架松旷、复合调整器松旷、滚轮运转和磨损异常、摆架变形等,应查明原因复原后才能使用。

In use, the working condition of the roller should be checked every shift. If the bolt is loose, the roller or swing frame is loose, the composite adjuster is loose, the roller is abnormal in operation and wear, and the swing frame is deformed, the reason should be found out before use.

如发现质量问题,不得自行拆卸,应与经销商协商修理或退还,也可直接与本公司联系。